Introduction

In the context of increasingly fierce global competition in furniture manufacturing and export, cost control has become a core concern for furniture companies and buyers. Whether it’s cabinets, wardrobes, office furniture, or custom furniture, the cost of hardware directly impacts the overall product’s profit margin and market competitiveness. For companies engaged in bulk purchasing, optimizing the cost of wholesale furniture hardware while ensuring quality and stable supply is a problem requiring systematic consideration.

Many buyers, when controlling costs, often focus only on the unit price, neglecting hidden costs such as structural selection, lifespan, logistics efficiency, and supply chain coordination. In fact, a reasonable hardware selection and procurement strategy can not only reduce direct procurement costs but also reduce after-sales issues and improve assembly efficiency, thereby achieving long-term, sustainable cost optimization. This article will analyze cost control strategies for wholesale furniture hardware from multiple perspectives to help furniture brands, manufacturers, and wholesalers make more rational decisions in actual procurement.

Impact of Raw Material and Structural Selection on Cost

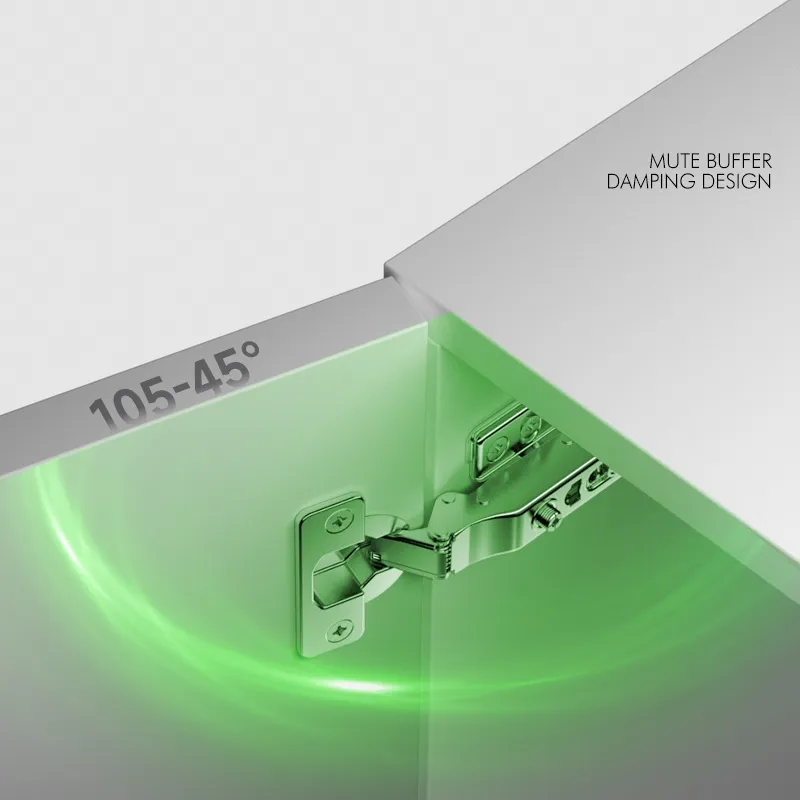

In the procurement of wholesale furniture hardware, raw materials and product structure are the primary factors determining cost. Taking hinges and drawer slides as examples, different steel grades, thicknesses, and surface treatments directly affect the unit price and lifespan of the product. For instance, cold-rolled steel, stainless steel, and galvanized steel differ significantly in cost and performance. For ordinary household furniture, the appropriate selection of cold-rolled steel combined with mature surface treatment processes can often effectively reduce costs while meeting functional requirements.

Structural design is equally important. Not all furniture requires high-load-bearing or complex hardware components. Some buyers excessively pursue “high specifications” during selection, leading to unnecessary cost increases. By communicating with professional suppliers and clarifying the actual usage scenarios, opening and closing frequencies, and load-bearing requirements of the furniture, the hardware structure can be matched more accurately, thus avoiding waste caused by over-performance in wholesale furniture hardware procurement.

Furthermore, standardizing structural specifications is also an effective way to reduce costs. By reducing the number of different models and specifications, mold costs can be reduced, inventory management simplified, and more competitive prices obtained in mass production.

Bulk Purchasing and Supply Chain Collaboration Strategies

Bulk purchasing is one of the core methods for reducing costs in wholesale furniture hardware, but this requires reasonable planning of the purchasing rhythm and quantity. While placing large orders at once can result in lower unit prices, it can also lead to warehousing and financial pressures if inventory turnover is not optimized. Therefore, a scientific purchasing plan should be based on actual order forecasts, production cycles, and sales rhythms.

Establishing long-term partnerships with suppliers is also an important strategy for cost optimization. Stable cooperation helps suppliers plan their production schedules in advance, reducing the additional costs caused by temporary adjustments, thus providing more support in terms of pricing. In the wholesale furniture hardware sector, many established manufacturers offer more flexible minimum order quantities, stable delivery times, and customized services to long-term customers.

Supply chain collaboration is also reflected in information transparency. By sharing demand changes, design adjustments, and market feedback in a timely manner, buyers and suppliers can jointly optimize product structure and production processes, thereby reducing overall costs while ensuring quality.

The Impact of Logistics and Packaging on Overall Costs

Logistics and packaging are often underestimated in the total cost structure of wholesale furniture hardware. In fact, for international trade and cross-regional supply, transportation and packaging costs can sometimes exceed the manufacturing cost of the product itself. Proper packaging design not only protects the product but also significantly improves packing efficiency and reduces transportation costs.

For example, hinges and drawer slides can increase the loading capacity of each container through standardized inner packaging and high-density packing designs, thereby spreading transportation costs. Some suppliers also optimize packaging solutions based on the customer’s mode of transport (sea, land, or multimodal transport), helping customers further reduce logistics expenses in wholesale furniture hardware procurement.

Furthermore, reducing unnecessary packaging materials and using recyclable or lightweight packaging not only helps reduce costs but also aligns with current market requirements for environmental protection and sustainable development.

Quality Stability and Long-Term Cost Control

Simply pursuing low prices often leads to higher hidden costs later on. For wholesale furniture hardware, quality stability directly relates to after-sales service rates, brand reputation, and customer satisfaction. Low-quality hardware may save on procurement costs in the short term, but frequent repairs, replacements, and customer complaints will result in higher overall costs in the long run.

Choosing manufacturers with robust quality management systems can effectively mitigate these risks. Stable product performance not only reduces rework and after-sales issues but also improves assembly efficiency and shortens production cycles. For furniture manufacturers, this stability itself is a cost advantage.

Furthermore, conducting regular quality spot checks and performance tests during wholesale furniture hardware procurement is a worthwhile cost control measure. Controlling quality issues early on can prevent significant losses from discovering defects only after large-scale production.

Conclusion: Systematic Thinking for Cost Optimization

In summary, cost optimization in wholesale furniture hardware is not about cutting corners in a single环节 (link/step), but a systematic process. From material and structural selection and bulk purchasing strategies to logistics, packaging, and quality management, every环节 (link/step) impacts the final cost. Truly effective cost control should be achieved through professional planning and supply chain collaboration, while ensuring product performance and reliability.

For furniture companies, instead of constantly changing suppliers in pursuit of the lowest price, it’s better to choose a partner that can provide stable quality, support customization, and has the capacity for large-scale production. Through long-term cooperation and continuous optimization, enterprises can not only reduce procurement costs but also improve overall operational efficiency, maintaining a competitive edge in the fierce market.

About Huiso Hardware

ハウソ・ハードウェア is a professional manufacturer specializing in hardware hinges and drawer slides, committed to providing high-quality, stable, and reliable hardware solutions to furniture brands and manufacturers worldwide. The company supports customization and wholesale services, covering a wide range of structures, specifications, and surface finishes to meet the needs of different furniture applications. With a mature production system, strict quality control, and flexible customization capabilities, Huiso Hardware has become a long-term trusted partner for many clients.