Abstract

Product life and stability in modern furniture and building hardware directly relate to customer experiences and brand reputation. All hardware components, including hinges, drawer slides, and handles, must not only withstand the friction and weight of daily use but also the corrosion of environmental moisture and oil. Therefore, hardware durability has become a core concern for furniture manufacturers, contractors, and wholesalers alike. Material selection and surface treatment methods for hardware components, such as hinges and drawer slides, most importantly, electroplating processes, have played a critical role in extending lifespan, maintaining aesthetics, and improving performance. Based on this, this article will introduce the electroplating process and the impact on hardware durability, including detailed material selection, types of electroplating, process flow, all the way to practical applications, and provide a systematic assessment and basis for enterprises and purchasers.

The Relationship between Material Selection and the Life of Hardware

To ascertain the durability of hardware components, one must start with the raw materials. Some common materials on the market include cold-rolled steel, zinc alloy, stainless steel, and copper alloy. The different mechanical properties of materials, their resistance to corrosion, and their processing features determine the long-term performance of hardware.

Materials and Durability

- Cold-rolled steel: Lower cost and easier to process, but prone to rusting without proper electroplating protection.

- Zinc alloy: Better corrosion resistance than cold-rolled steel with a slight reduction in hardness; slight deformation may occur under long-term heavy loads.

- Stainless Steel: A generally high-strength and excellent corrosion-resistant alloy, it usually finds favour as the material in expensive hardware for furniture.

- Copper alloy: Aesthetically pleasing and corrosion-resistant but more expensive. Good for decorative hardware.

Example: A kitchen cabinet manufacturer used cold-rolled steel hinges but didn’t pay attention to surface treatment. After six months, some hinges showed rust spots, at which point customers started complaining. By using stainless steel or good-quality electroplating, the hardware durability significantly improved; it could be used steadily for several years without rust.

Tips for Material Selection

- Material selection should be based on usage environments: kitchen, bathroom, bedroom, etc.

- Increase the corrosion resistance by electroplating.

- Hardness and load-bearing capacity shall be focused on to avoid any deformation in long-term use.

Materials are the basis of hardware performance. Even with the most advanced electroplating process, without suitable raw materials, hardware cannot be guaranteed to be durable.

The Impact of Electroplating Type on Durability

Electroplating is an important process that enhances the durability of hardware. The different categories of electroplating treatments directly affect the performance and beauty of the hardware.

Common Types of Electroplating

- Zinc Plating: Generally applied to cold-rolled steel for the purpose of forming a rustproof protective layer. Advantages: low cost and simple operation; salt spray test life generally 24–48 hours.

- Nickel Plating: Stronger corrosion resistance than zinc plating, smooth and attractive surface; suitable for high-end furniture hardware.

- Chromium Plating: Commonly used for decorative hardware, wear-resistant and corrosion-resistant, high surface brightness; salt spray test life 96–120 hours.

- Multi-layer Electroplating (Copper+Nickel+Chromium): Integrates advantages of each layer, significantly improving corrosion resistance and gloss, ideal for reinforcing hardware durability.

Example: High-end cabinet drawer slides have a multi-layer copper-nickel-chromium electroplating process. No rust spots appeared after a 96-hour salt spray test; their lifespan is 2–3 times longer than single-layer galvanized hinges.

Selection Tips for Electroplating

- Parts used in a high-humidity environment should use multi-layer electroplating or stainless steel.

- For components that bear weight or experience frequent friction, choose plating layers with high hardness and wear resistance.

- Thickness and uniformity should be checked in electroplating to avoid areas that are too thin, which can cause early corrosion.

Scientific selection and quality control of electroplating types ensure hardware durability.

Electroplating Process and Quality Control

Even with high-quality material and suitable plating types, poor process flow and quality control can still affect the hardware durability of components.

Standard Process Flow

- Cleaning and Degreasing: Ensure surfaces are free from oil, dust, and oxides.

- Pickling or Activation Treatment: Increase metal surface adhesion and enhance plating durability.

- Underlying Copper/Nickel Plating: Enhance corrosion resistance and hardness.

- Chromium/Nickel Decorative Layer Plating: Improve brilliance and aesthetics.

- Passivation Treatment or Sealant Coating: Further enhance corrosion resistance.

Key Quality Control Points

- Electroplating Thickness Inspection: Good quality hardware usually has plating thickness of 10–15 microns.

- اختبار الرذاذ الملحي: Simulates a high-humidity environment to assess corrosion resistance.

- Adhesion Test: Ensures plating does not peel off or blister easily.

Example: A hardware supplier’s slide rail product, if pickling or underlying copper plating was neglected, would develop surface peeling and rust after six months, with hardware durability far below standard requirements. By optimizing the process and strictly controlling plating thickness, the product’s service life can be doubled.

The Impact of Environmental Factors and Conditions of Use

Even with good materials and electroplating, the actual usage environment is another factor affecting hardware durability. Humidity, temperature, air salinity, and chemical contact can accelerate corrosion or wear.

Common Environmental Problems

- High humidity in kitchens and bathrooms can cause premature rusting of galvanized hinges.

- High salt content in coastal areas accelerates metal oxidation; insufficient plating thickness leads to failure.

- High-frequency usage scenarios, like desk drawers and cabinet slides, accelerate plating wear.

Usage and Maintenance Recommendations

- Select proper materials and electroplating types according to the environment.

- Clean hardware regularly to prevent long-term accumulation of oil and scale.

- For highly loaded or frequently used components, use stainless steel or multi-layer electroplated materials.

Scientific selection and maintenance based on environment and usage can greatly extend hardware durability and reduce after-sales costs.

The Importance of Installation and Post-Maintenance

Correct installation and maintenance directly affect hardware durability. Improper installation can lead to uneven stress on hinges or slides, loose screws, or accelerated local wear, shortening lifespan.

Installation Points

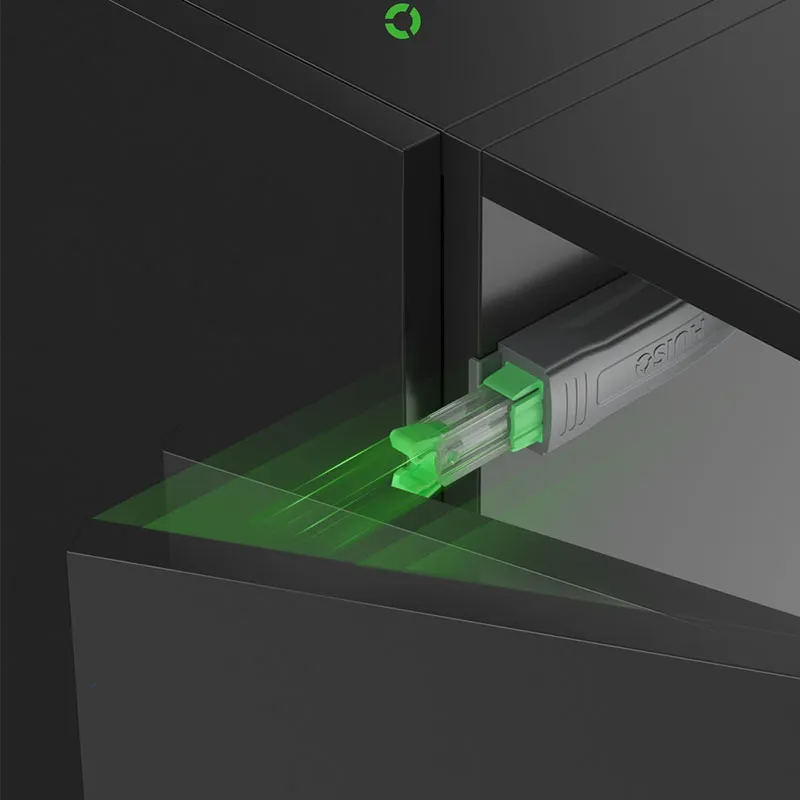

- Precisely measure hole positions for a proper fit between hardware and doors or drawers.

- Use recommended screw specifications and torque to avoid localized stress.

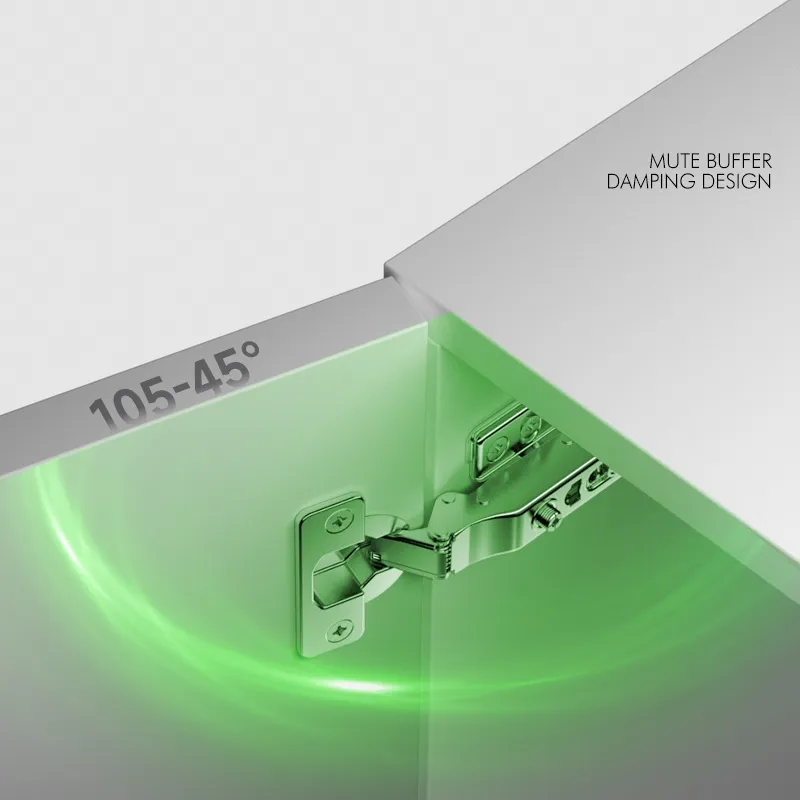

- After installation, check smoothness of opening/closing and adjust damping or slides if needed.

Post-Maintenance Tips

- Clean surfaces frequently to maintain plating integrity.

- Check screw tightness to avoid loosening and wear.

- Lubricate drawer slides and damping hinges to reduce friction and extend life.

Proper installation and maintenance maximize the benefits of materials and electroplating for hardware durability, ensuring long-term stability.

Conclusion

Hardware durability depends not only on material selection but also on electroplating type, process flow, environmental conditions, and installation and maintenance. Appropriate material selection, scientific electroplating, strict process control, and proper installation and maintenance can greatly improve the hardware durability of furniture hinges, drawer slides, and other components, guaranteeing long-term stable use and good customer experience. This understanding helps purchasers, manufacturers, and contractors make professional and reliable judgments in selection and quality control.

About Huiso Hardware

هويسو هاردوير is a professional manufacturer of hinges and drawer slides, supplying hydraulic hinges, three-section drawer slides, and concealed slides, and providing OEM/ODM customized services. The company emphasizes careful material selection and strict electroplating process control to ensure hardware durability, guaranteeing the quality of each product. With high-quality products, flexible customization options, and wholesale supply advantages, Huiso Hardware has experienced rapid growth in recent years, providing highly reliable hardware to furniture manufacturers, cabinet factories, and engineering customers worldwide.