Drawer Slide Problems 1:The drawer is Hard to remove or install

Symptoms: The Drawer is stuck or difficult to detach.

Causes:

– Locking tabs or release levers are stiff.

– Dirt, sawdust, or foreign objects in the track.

Fix:

– Check for release levers on the slide rail; gently lift or press them while pulling the drawer.

– Use a vacuum and a cloth to remove dirt inside the track.

– Apply silicone-based lubricant.

QC Tip: In factory production, a manual pull test on 10% of assembled drawers is performed.

Drawer Slide Problems 2:Drawer Doesn’t Stay Closed

Symptoms: The Drawer slides open on its own.

Causes:

– Improper front tilt or drawer misalignment.

– Weak or missing rubber stoppers.

– Poor spring tension in soft-close mechanisms.

Fix:

– Use a level to ensure the drawer and slide rails are aligned.

– Adjust cabinet installation.

– Replace soft-close slides with failed tension.

QC Tip: Check closure resistance using a bounce-back test: the drawer should remain closed when lightly tapped.

Drawer Slide Problems 3:Drawer Slides are Jerky or Sticky

Symptoms: The Drawer doesn’t glide smoothly; it gets stuck halfway.

Causes:

– Debris in the ball-bearing track.

– Warped slide rails due to poor packaging or handling.

Fix:

– Remove the drawer and clean the ball-bearing track.

– Use high-quality lubricants.

– Replace bent slides.

QC Tip: Test slide function with a 15kg load for smoothness.

Drawer Slide Problems 4:Drawer Feels Loose or Wobbly

Symptoms: Side-to-side movement or drawer rattles when opening.

Causes:

– Improper slide width or installation.

– Screws are missing or loose.

Fix:

– Ensure correct drawer slide type (e.g., 45mm side-mount vs 27mm under-mount).

– Tighten all screws using a screwdriver or drill.

QC Tip: Use minimum 4-point screw check per side during assembly.

Drawer Slide Problems 5:Drawer Can’t Fully Extend or Close

Symptoms: The Drawer doesn’t open fully or stops short when closing.

Causes:

– Slide rails are misaligned or bent.

– Interference from cabinet structure or internal obstructions.

Fix:

– Realign both slide rails using a level tool or jig fixture.

– Check internal cabinet clearance and ensure no warping.

QC Tip: Simulate full extension/closure cycles on production line using load tests (e.g. 25kg for 10,000 cycles).

Drawer Slide Problems 6:Drawer Slides Are Noisy

Symptoms: Grinding, squeaking, or clicking sounds during movement.

Causes:

– Insufficient or poor-quality lubrication.

– Ball bearing defects or debris caught in the rail.

Fix:

– Clean all moving parts with a lint-free cloth.

– Apply high-grade lubricant suitable for metal surfaces.

– Replace noisy slides if bearings are damaged.

QC Tip: Implement random batch sound checks in a quiet testing environment. Slides should operate under 40 dB if using soft-close systems.

Drawer Slide Problems 7:Drawer Slides Rust or Show Premature Wear

Symptoms: Visible rust, especially on inner tracks or mounting brackets.

Causes:

– Low-grade materials or poor electroplating.

– Humid storage or high-moisture usage environments (e.g., bathrooms, coastal areas).

Fix:

– Use drawer slides with 48–72 hour salt spray tested plating (e.g., zinc, nickel).

– Store finished goods in climate-controlled warehouses.

– Consider stainless steel or black powder-coated slides for heavy-duty usage.

QC Tip: Perform salt spray corrosion testing (ASTM B117 standard) for each batch of hardware components.

Quick Summary of Common Drawer Slide Problems & Fixes

| Problem | Cause | Solution | QC Tip |

| Difficult drawer removal | The drawer won’t stay closed | Lubricate and use tools gently | Manual drawer removal tests |

| Adjust/bend the slide front | Front tilt / deformed slide head | Poor lubrication/bearing issues | Bounce-back simulation test |

| Jerky drawer motion | Dirty or warped rails | Clean & lubricate | Smoothness test under load |

| Drawer feels loose | Weak or missing screws | Use 20mm self-tapping screws | Torque check on installation points |

| Incomplete extension/closure | Misalignment | Realign rails and cabinet edges | Full-travel inspection |

| Noisy operation | The drawer feels loose | Clean and lubricate or replace slides | 40 dB acoustic test |

| Rust or premature wear | Poor material/plating | Use corrosion-resistant plating | Salt spray test (ASTM B117) |

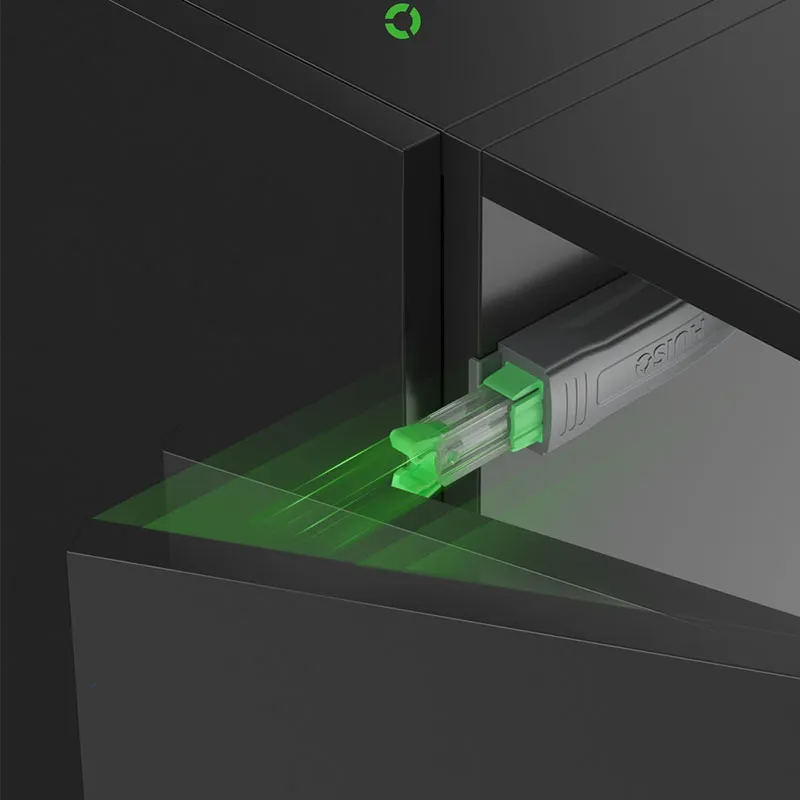

Choose Huiso Hardware for Drawer Slides You Can Trust

If you’re a furniture factory or global hardware distributor tired of dealing with drawer slide problems, Huiso Hardware is here to help.

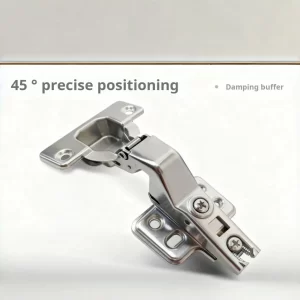

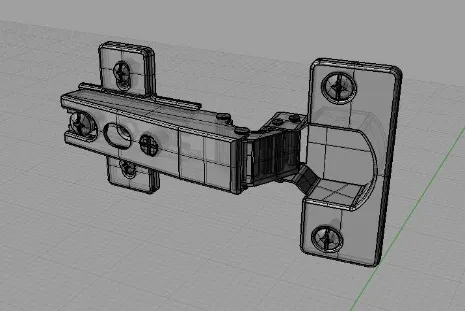

We are a professional drawer slide and cabinet hinge manufacturer offering:

– Custom wholesale solutions

– 100,000-cycle durability testing

– Corrosion-resistant finishes

– OEM/ODM support for your market

– Strict quality control with full documentation

Our engineers and QC teams collaborate closely with clients to design and deliver drawer slides that perform smoothly, quietly, and reliably — even under extreme use.

Visit Huiso Hardware’s product center, contact us now to request a sample, or get a factory quote.