Introduction

In the structural design of cabinets, wardrobes, and various types of furniture, hinges are often overlooked yet extremely crucial components. Different hinge types not only determine the opening angle, smoothness, and lifespan of cabinet doors, but also directly affect the overall appearance and installation method. For furniture manufacturers, custom cabinet makers, and wholesale buyers, correctly understanding the differences between various hinges is an important step in controlling costs, improving quality, and meeting customer needs. This article will systematically compare the three most common hinge types to help you fully understand their differences in terms of function, structure, and application scenarios. When choosing the right solution, a thorough understanding of the characteristics of hinge types can often avoid rework and hidden costs, bringing long-term value to the project.

Structural and Application Advantages of Full Overlay Hinge

Full Overlay Hinge is a solution used very frequently in modern cabinets. “Full overlay” means that the cabinet door almost completely covers the cabinet side panel when closed, leaving only a very small gap between the doors. This structure is ideal for home designs that favor a minimalist, modern style.

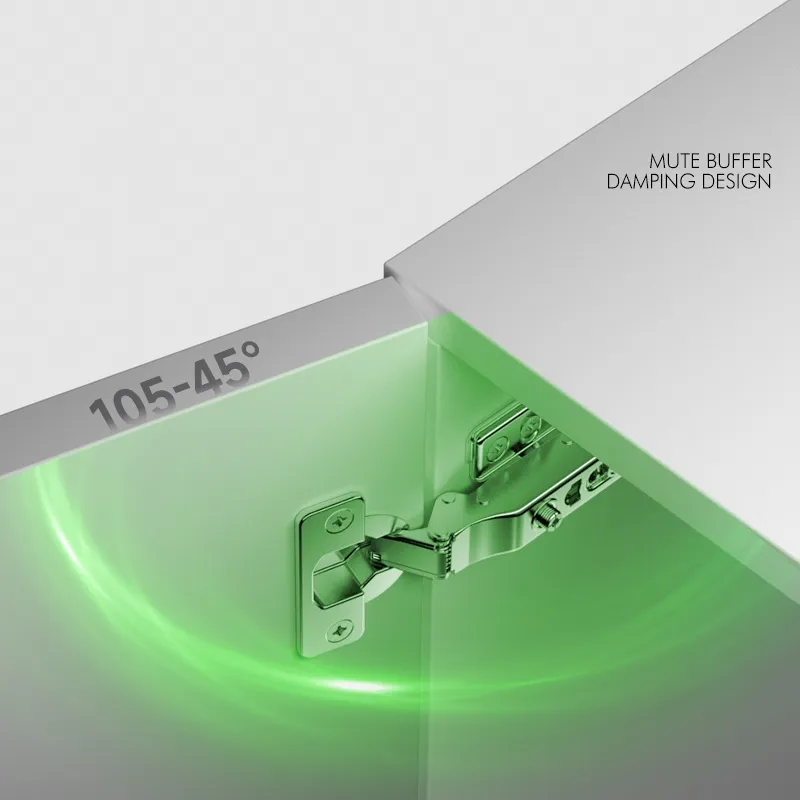

From a technical perspective, full overlay hinges typically use 35mm cup holes, allowing for opening angles of 100°–110°, with some high-end models even supporting over 120°. Data shows that in North America and Europe, full overlay hinges account for over 60% of integrated kitchen projects, primarily due to their strong visual uniformity and wide range of installation adjustments. For novice installers, choosing the right hinge types can effectively reduce door panel misalignment issues.

In terms of practical tips, when installing full overlay hinges, it is crucial to match the door panel thickness with the hinge arm length. If the door panel is thick (for example, over 20mm), an extended arm design should be chosen to prevent interference between the door panel and side panels when opening. Furthermore, in mass production, using full overlay hinges with a soft-closing buffer function can significantly reduce after-sales maintenance rates. This has become a key consideration for many furniture factories when evaluating hinge types.

Flexibility and Cost Balance of Half Overlay Hinge

Half overlay hinges are commonly used in structures where two doors share a single side panel. Unlike full overlay hinges, each door only covers half of the side panel, resulting in a more visually noticeable gap. This design achieves a good balance between space utilization and cost control.

In terms of application scenarios, half overlay hinges are very common in office furniture, filing cabinets, and some budget-oriented cabinets. For example, in a standard 600mm-wide cabinet, a half overlay structure allows two doors to be installed on the same side panel, reducing material usage by approximately 15%–20%. This material-saving advantage is particularly important for high-volume projects when evaluating hinge types.

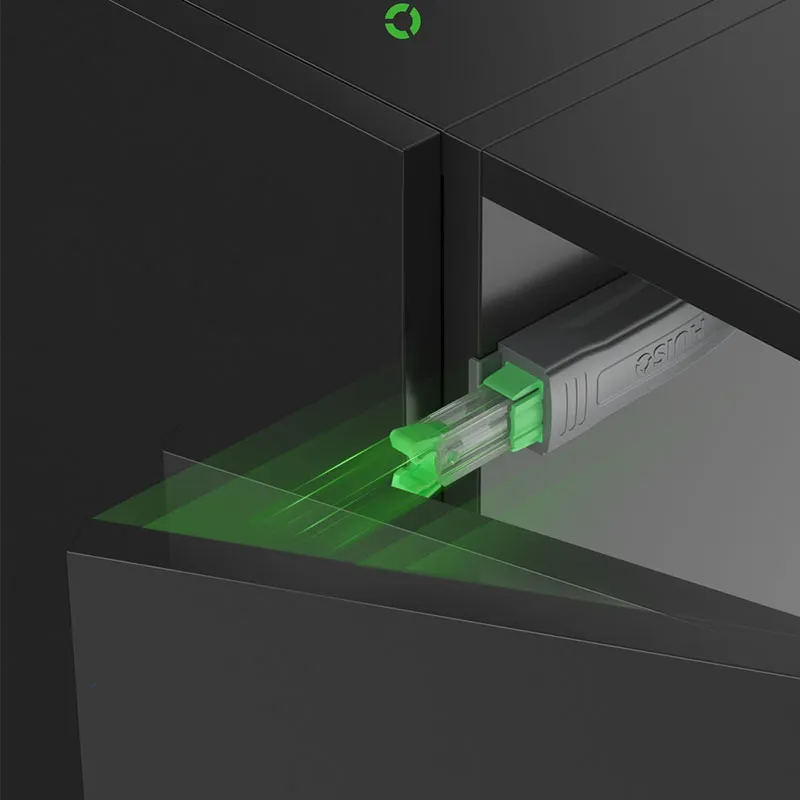

Regarding installation considerations, half overlay hinges require higher positioning accuracy. If the cup hole deviation exceeds 1mm, the door gap will become noticeably uneven. It is recommended to use precision positioning drilling equipment during production and to make repeated adjustments during the trial assembly stage. By properly understanding the installation tolerances of different hinge types, manufacturers can significantly improve the consistency and overall quality of the finished product.

Aesthetic Value and Technical Requirements of Inset Hinge

Inset hinges represent a more upscale and traditional style option. Their key feature is that the cabinet door is completely embedded within the cabinet body, remaining flush with the cabinet surface. This results in a refined, high-end appearance that is particularly popular in solid wood furniture and premium custom cabinetry projects.

However, inset hinges require significantly higher manufacturing precision than the previous two options. Industry experience suggests that the dimensional error between the cabinet interior and the door panel must be controlled within ±0.5mm. Otherwise, problems such as door friction, poor closing, or uneven gaps may occur. Therefore, when selecting hinge types, inset hinges are generally more suitable for manufacturers with mature production processes and stable quality control systems.

In terms of practical usage, it is advisable to choose three-way adjustable inset hinges, which allow for fine adjustments after installation. In addition, inset structures typically reduce internal storage space by approximately 5%–8%. This limitation should be clearly communicated to customers during the design stage to avoid misunderstandings. A clear understanding of these details helps decision-makers choose hinge types that align more accurately with project positioning and customer expectations.

Comprehensive Comparison and Selection Recommendations for Different Hinge Types

In real-world projects, there is rarely a one-size-fits-all hinge solution. Full overlay, half overlay, and inset hinges each have their own strengths and limitations. From a cost perspective, full overlay hinges tend to have a slightly higher unit price but offer better installation efficiency and visual consistency. Half overlay hinges provide advantages in material utilization and cost control, while inset hinges stand out for their premium appearance and craftsmanship.

When selecting hinges, it is helpful to evaluate three key dimensions. First is design style: modern and minimalist furniture designs are usually better suited to full overlay structures. Second is budget and production scale: large-scale projects with tight cost controls often benefit from half overlay hinges. Third is manufacturing capability: only factories with high precision and stable processes can reliably produce inset hinge structures. A systematic comparison of hinge types allows design, production, and sales teams to reach consensus more easily, reducing communication costs and project risks.

Conclusion

In conclusion, Full Overlay, Half Overlay, and Inset Hinges do not have absolute advantages or disadvantages. The most important factor is whether the chosen hinge type matches the specific application scenario. Understanding structural differences, installation requirements, and long-term performance is the foundation for making rational and cost-effective decisions. For purchasing professionals, a deep understanding of hinge types helps achieve the best balance between quality, cost, and delivery schedules. By investing time and effort in the early selection stage, manufacturers and suppliers can ensure smoother production processes and better end-user satisfaction, ultimately creating greater long-term value.

About Huiso Hardware

Huiso Hardware is a professional manufacturer specializing in metal hinges and drawer slide systems, providing stable and reliable hardware solutions to customers worldwide. The company supports both customization and wholesale services, allowing specifications and functions to be flexibly adjusted according to different market demands. No matter which hinge types you are evaluating, Huiso Hardware, with its mature manufacturing experience and strict quality control standards, can provide dependable support for your projects.