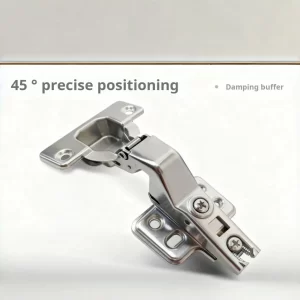

Cabinet hinges, as a fundamental component of kitchen furniture, are tasked with the mere function of opening and shutting cabinet doors. With the growing demand for custom cabinetry, clients are placing more consideration on the quality of cabinet hinges, particularly in terms of materials and surface treatment. Custom cabinet hinges must be not only tough but also handsome. Today we are going to witness how surface treatment technology can be utilized to create custom cabinet hinges tougher and more handsome.

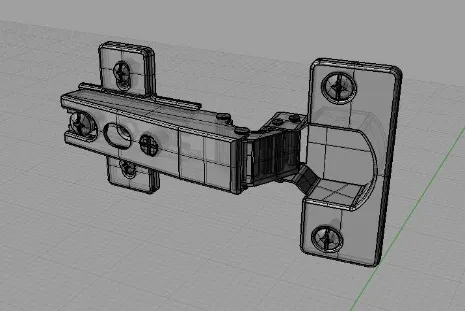

Discovering the Materials of Custom Cabinet Hinges

Let us first familiarize ourselves with the typical materials of custom cabinet hinges like stainless steel, cold-rolled steel, and aluminum alloy before bringing in the surface treatment technology.

304 Stainless Steel Hinges

304 stainless steel hinges are the optimum selection for high-quality custom cabinet hinges due to corrosion resistance and strength. They ensure long-term stability in kitchen humid conditions.

Cold-Rolled Steel Hinges

Cold-rolled steel hinges are more powerful and resistant. Electroplating offers acceptable corrosion resistance, thus extending their lifespan.

Aluminum Alloy Hinges

They are lighter in weight but possess good corrosion resistance and are therefore most suited for light cabinets. Having an idea about materials used to make hinges, let’s identify how we can improve them by using surface treatments.

Popular Surface Treatment Processes

Cabinet hinge surface treatment directly affects their looks as well as longevity. There are some common surface treatments that involve:

Electroplating

Electroplating is one way of coating the surface of the hinge with a layer of metal (say, zinc, nickel, or chromium) through electrolysis. This process effectively shields the metal from being contacted by the outside world, preventing corrosion and imparting its characteristic brightness to the hinge.

Painting/Powder Coating

Weather-resistant coating using spraying or electrostatic powder coating technology offers the hinge a second layer of corrosion and wear resistance protection. Besides this, painting also offers color options for different consumer appearances.

Passivation

Passivation is a chemical treatment that forms a protective layer by the process of oxidation, thus increasing corrosion resistance of the hinge along with giving a visually attractive smooth finish.

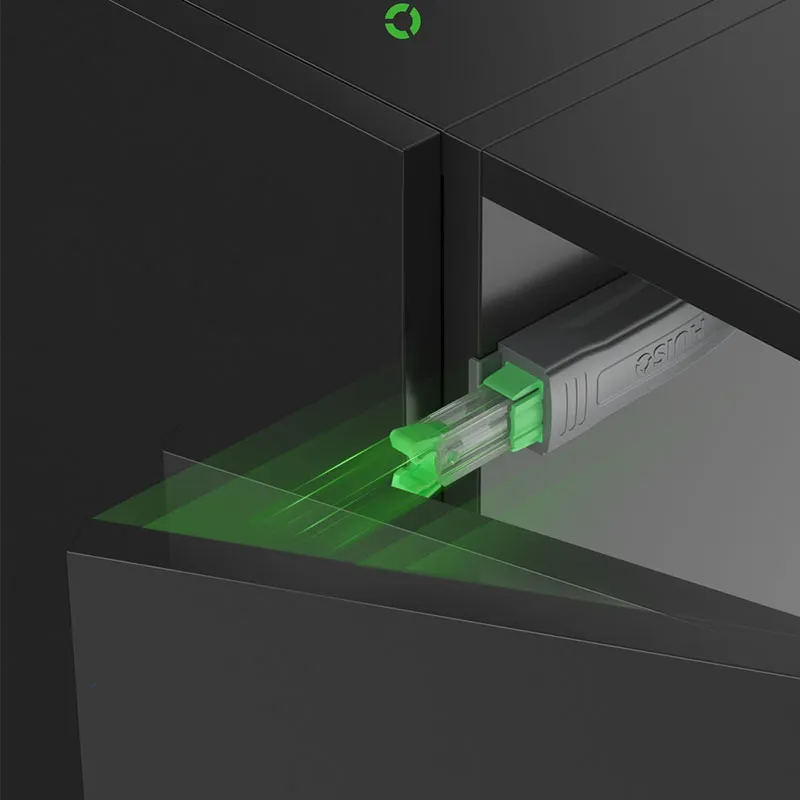

PVD

Physical vapor deposition (PVD) produces a hard, wear-resistant film on the hinge surface, which increases strength and improves metallic gloss.

Dacromet Treatment

Dacromet is an anti-corrosion treatment that is chromium-free and forms a strong protective film on the hinge surface. It is widely applied where high corrosion resistance is required.

Surface Treatment Improves Custom Cabinet Hinge Life

Durability of hinges is one of the most significant issues for consumers. Surface treatment technology maximizes the life of hinges in the following manners:

Improved Corrosion Resistance

Treatments to the surface such as electroplating and passivation work effectively to protect the metal from exposure to oxygen and water, thereby inhibiting rust and corrosion and enabling the hinges to endure long-time usage in humid kitchen environments.

Improved Wear Resistance

Hinges tend to wear and tear due to frequent opening and closing. Surface treatments such as PVD treatment have the ability to create a wear-resistant film on the hinge surface, significantly improving its wear resistance and service life.

Improved Impact Resistance

Hinges are also subject to impacts during opening and closing. Effective surface treatments make the hinge more resistant to impact and harder, and hence improve its impact resistance.

Surface Treatment Enhances Custom Cabinet Hinges’ Appearance

In addition to providing durability, surface treatments can significantly enhance hinge appearance:

Color Selection

Electroplating, PVD, and chemical coloring methods offer a broad range of colors, such as silver, gold, and black, for the consumer to select the right color hinge to complement the cabinetry theme.

Unique Textures

Brushed and sandblasted finishes can provide unique textures to hinges, enhancing their visual appeal. For example, brushed finishes can provide a soft metallic texture, perfect for modern cabinet designs.

High-Gloss Mirror Finish

Polished finishes create a mirror finish, perfect for high-end, luxurious cabinet designs, giving an actual visual impact.

How to Choose the Best Surface Treatment

While choosing custom cabinet hinges, shoppers should remember the following:

Kitchen Environment

In case corrosive or damp kitchen surroundings are present, there is a requirement to choose hinges of improved corrosion resistance, for example, stainless steel hinges that are electroplated, passivated, or treated with Dacromet.

Cabinet Style

Cabinet style also influences the choice of hinges. Plain modern cabinets can use hinges with brushed or sandblasted finishes, while the traditional classy cabinets would suit hinges with polished or mirrored finishes.

Budget Concerns

Different finishes on the surface cost differently. Electroplating and PVD are more expensive, while painting or sandblasting are cheaper, but offer great corrosion resistance and appearance.

About Huiso Hardware

Quincaillerie Huiso is a specialized custom hardware hinge and slide manufacturer with an aim to serve customers with durable, high-quality, and elegant cabinet hinge solutions. We offer wholesale customers worldwide a complete range of wholesale custom services for every hinge to undergo the right surface treatment for enhanced corrosion resistance, wear resistance, and appearance. Regardless of whether electroplating, painting, PVD, or passivation, Quincaillerie Huiso can supply the most suitable custom hinge solution to meet your application. Utilize Huiso Hardware to make your cabinet hinges not only durable but also beautiful.