In modern furniture and home hardware manufacturing, the quality of hinges and slides directly determines the lifespan and user experience of furniture. A seemingly ordinary door hinge or drawer slide actually embodies complex craftsmanship and rigorous testing procedures. For hardware manufacturers, distributors, and buyers, understanding the evaluation standards for hinge testing and slide durability is crucial to ensuring product quality and brand reputation. This article will delve into how to scientifically evaluate hinge and slide quality based on five core testing standards. It will also incorporate practical examples and international certification systems to help companies establish an efficient quality control system.

Cycle Life Test

Cycle life testing is the most fundamental and crucial standard for hinge testing and slide durability. It simulates the repeated opening and closing movements of hinges or slides in daily use, verifying the stability and reliability of the product over time.

Testing Principles and Standards

The internationally accepted testing method involves performing at least 50,000 to 100,000 opening and closing cycles under specified load conditions. According to the ISO hinge factory standard, hinges must continue to open smoothly without loosening or breaking after testing, while slides must maintain smooth sliding and pulling without noticeable noise.

Real-World Examples

Take kitchen cabinet doors, for example, which open and close an average of 10 times a day. If a hinge passes 100,000 cycles, it can provide at least 27 years of reliable service. Statistics from a well-known furniture brand show that hinges that fail cycle life testing have a replacement rate as high as 12%, while certified products have a replacement rate of less than 1%.

Tips and Suggestions

Companies can use automated cycle testing equipment for batch testing, incorporating sensors to record changes in resistance during each opening and closing cycle, enabling more accurate analysis of wear trends. This not only improves quality control but also optimizes product structural design.

Corrosion Resistance Test

Hardware is often exposed to moisture, oil, smoke, and acidic and alkaline environments, so corrosion resistance is a key quality indicator. Products used in kitchens, bathrooms, or outdoor environments, in particular, must undergo rigorous hinge testing to ensure long-term stability.

Testing Methods

Common corrosion resistance tests include the Salt Spray Test and the Humidity Test. According to the ISO hinge factory standard, products must withstand a neutral salt spray environment for at least 96 hours without visible rust or peeling of the plating.

Data and Comparison

Under the same conditions, nickel-plated hinges offer approximately three times the corrosion resistance of ordinary electroplated products. Slide rails using a zinc plating and electrophoresis process can maintain over 90% of their finish after a 96-hour salt spray test. This scientific quality control process effectively extends product life and reduces after-sales risks.

Practical Application Recommendations

When evaluating slide durability, companies should select different anti-rust processes based on different usage environments. For example, electrophoretic anti-rust slides are recommended for kitchens, while stainless steel hinges can be considered for bathroom products. Corrosion resistance test results can provide customers with more targeted selection recommendations.

Load Bearing Test

Load-bearing performance directly determines whether a hinge or slide can support the overall weight of the furniture and is a key component of hinge testing and slide durability.

Testing Process

This test typically involves applying a load and performing an opening and closing cycle to detect deformation or functional impairment. For example, for slides, standard load-bearing tests are typically conducted at 30kg, 45kg, or 60kg. After 5,000 consecutive push and pull cycles, the slides must maintain a smooth sliding motion.

Case Study

Huiso Hardware sets a load-bearing standard of 1.5 times the national standard in its slide quality control system. For example, a slide rated at 30kg was tested to withstand a 45kg load and complete 10,000 cycles without deformation. This performance advantage earned the product a high score in ISO hinge factory certification.

الملاحظات

When conducting load-bearing tests, attention should be paid to load distribution. Excessively concentrated loads can lead to increased local stress, affecting the evaluation results. It is recommended to incorporate the three-point load principle when evaluating slide durability to ensure scientific data integrity.

Noise & Smoothness Test

User experience is a crucial factor in evaluating hardware quality. Even the most durable hinges or slides will fail to achieve user satisfaction if they exhibit noise, sticking, or uneven resistance.

Test Method

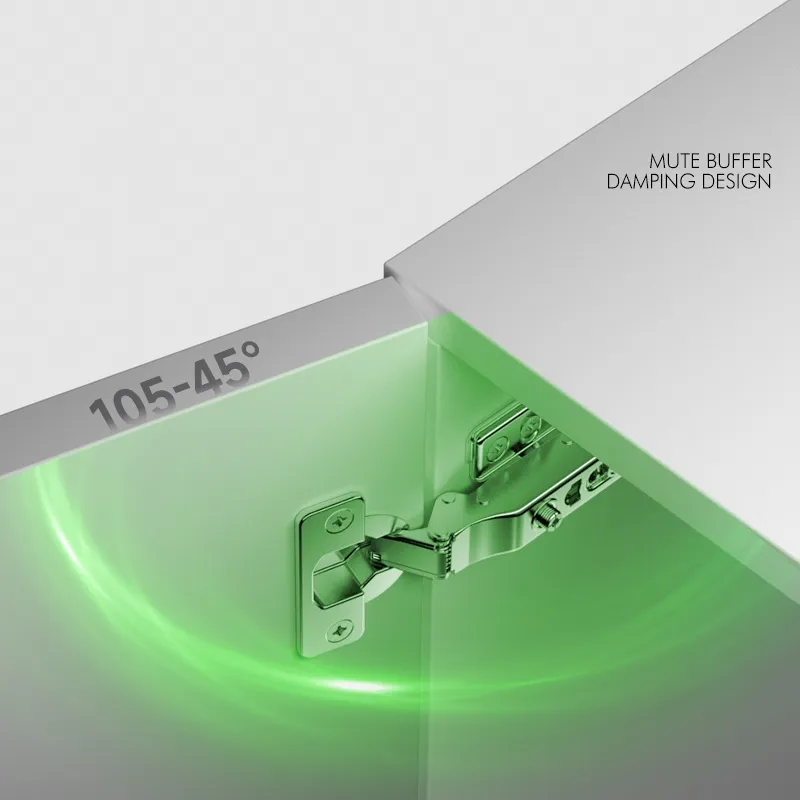

This test is a dynamic performance test requiring a noise meter and a resistance measurement device. During continuous opening and closing, or pushing and pulling, the noise level (in dB) and the change in the sliding resistance curve are measured. According to the ISO hinge factory standard, noise levels should be kept below 40dB, and sliding resistance fluctuations should not exceed ±10%.

Measured Data

Experiments show that slides using a ball bearing structure produce 20% less noise on average than conventional slides, and resistance fluctuations are less than 5% after long-term use. Hinges with a cushioning structure, during hinge testing, achieve impact-free opening and closing, significantly improving the user experience.

Quality Optimization Suggestions

During the quality control process, companies should include noise testing and optimize product performance through parameters such as lubricant type and plastic cushioning material. For high-end furniture manufacturers, silent slides and damping hinges have become standard features.

Dimension & Tolerance Testing

Precision is a key indicator of hardware manufacturing quality. Improper dimensional deviation or tolerance control not only affects assembly accuracy but can also shorten product life.

Testing Requirements

According to the ISO hinge factory standard, hinge axis deviation should be controlled within ±0.05mm, and rail parallelism error should not exceed ±0.1mm. High-precision testing is achieved using precision measuring tools and coordinate measuring machines (CMMs).

Practical Impact

During a slide durability assessment, it was discovered that a 0.2mm deviation in the rail hole position of a certain brand resulted in an assembly difficulty rate of 15%. However, after implementing CNC precision machining to control tolerances, the product assembly pass rate increased to 99.8%.

Technical Key Points

Precision control relies not only on equipment but also on the rigor of the quality control system. Huiso Hardware implements multi-point dimensional inspection and automated data comparison on the production line to maintain micron-level deviations for each batch of products, ensuring consistent product quality.

Conclusion

Evaluating hinge and rail quality is more than just a simple visual inspection; it requires a systematic, data-driven engineering process. Through hinge testing, slide durability verification, and a rigorous quality control system, manufacturers can ensure their products remain reliable, safe, and smooth over long-term use. Five key testing criteria—cycle life, corrosion resistance, load-bearing capacity, noise and smoothness, and dimensional tolerance—form the core framework for international hardware quality assessment. For companies pursuing high-end quality and international market competitiveness, adhering to ISO hinge factory standards is essential for earning customer trust and enhancing brand reputation.

About Huiso Hardware

هويسو هاردوير is a modern company specializing in the manufacture of hardware hinges and slides, dedicated to providing high-quality, customizable hardware solutions to customers worldwide. Equipped with advanced automated production equipment and a comprehensive quality control system, the company conducts rigorous testing throughout the entire process in accordance with ISO standards. Whether through high-intensity hinge testing or long-term slide durability verification, Huiso Hardware earns customer trust with its superior manufacturing process and consistent quality.

Huiso Hardware offers OEM/ODM customization and wholesale services. We strive to ensure that each product serves as the strongest and smoothest connection point in furniture construction.

For more information, please visit our official website or contact our sales team for professional technical support.

Related Products

-

Bulk 30 Degree Hinge For Cabinet

-

مفصلات الإغلاق البطيء للخزانة بالجملة مفصلات الإغلاق البطيء للخزانة السائبة مفصلة الغمر بالماء بزاوية صفرية-H01

-

مفصلة أدوات الخزانة المفصلية الهيدروليكية المخصصة للمطبخ أو الحمام-HB2

-

مفصلات خزانة المطبخ ذات الإغلاق الناعم المخصص مفصلات الأبواب السميكة والرقيقة ذات الزاوية الصفرية-HB6