Introduction

In modern furniture manufacturing, the quality of hinges directly affects the smoothness of cabinet doors, noise levels, and overall lifespan. Whether it’s kitchen cabinets, wardrobes, bathroom vanities, or office furniture, any door panel structure relies on a stable and reliable hinge system. For furniture brands, contractors, wholesalers, or factory buyers, assessing hinge quality is a crucial step in ensuring product performance and brand reputation. However, for many buyers and furniture factories, hinges often “look similar,” but the actual user experience can be vastly different. Therefore, mastering scientific, professional, and easy-to-use assessment methods is essential.

This article, based on experience in the hardware industry, summarizes six simple yet professional hinge quality assessment methods to help you avoid pitfalls when selecting, inspecting, or wholesaling hinges, ensuring long-term stable operation. Through these methods, you can not only quickly identify hinge quality but also communicate technical requirements more systematically with suppliers, thereby improving the overall hardware configuration standards for your furniture. The following content will comprehensively analyze the core criteria for judging hinge quality from multiple perspectives, including structural design, material processing, durability testing, damping effect, and installation performance.

Checking Structural Design and Manufacturing Precision

To judge hinge quality, the first thing to focus on is the hinge’s structural design and manufacturing precision—this is the primary factor affecting stability, load-bearing capacity, and lifespan. High-quality hinges have a high degree of precision in key components such as the hinge cup, base, pivot, and spring. For example, a hydraulic hinge contains an oil core, damping lines, and spring components; if the design is unreasonable or the manufacturing tolerances are too large, it will lead to uneven closing speed, abnormal noise, or even breakage.

From a consumer’s perspective, the following methods can be used to judge:

- Observe the thickness of the hinge cup and base: High-quality cold-rolled steel is typically 1.0–1.2mm thick; hinges that are too thin are prone to deformation.

- Check the uniformity of welding: Inferior hinges have rough and asymmetrical welds, while high-end hinges have fine welds with a protective layer.

- Check the tightness of the connection parts: When you shake the hinge by hand, there should be no obvious gaps or “play” in the movement.

An industry standard dictates that when the error between the hinge body and the base is controlled within ±0.05mm, the hinge’s operational stability is significantly improved. Conversely, products with an error greater than 0.1mm often experience misalignment of door panels during mass assembly. Therefore, good structural design and precision are fundamental to improving hinge quality.

Material and Electroplating Process Affect Corrosion Resistance

When evaluating hinge quality, material selection and electroplating treatment are equally crucial. Hinges are exposed to moisture, grease, and cleaning agents during use, making corrosion resistance particularly important in kitchen and bathroom environments. Common materials on the market include cold-rolled steel, zinc alloy, and stainless steel. Cold-rolled steel is less expensive but relies on an electroplating layer for protection; stainless steel hinges are more suitable for spaces with higher humidity.

The following are suggested methods for judging hinge quality:

- Check the gloss of the electroplating layer: High-quality electroplating presents a smooth, uniform finish without any blooming.

- Compare salt spray test data: The industry standard is 48 hours, while high-end brands can achieve 96–120 hours.

- Check scratch resistance: Lightly scratch the surface. If the underlying material is immediately exposed, the electroplating layer is too thin.

High-quality electroplating typically includes a multi-layered structure of copper, nickel, and chromium, with a total thickness consistently between 10–15 micrometers. This is crucial for improving hinge quality. For products intended for export, many countries have specific standards for surface corrosion levels. Therefore, choosing reliable materials and electroplating processes can effectively improve the long-term performance of the hinge.

Durability Testing is Key to Measuring Lifespan

Durability testing is one of the most intuitive and effective methods for evaluating hinge quality, especially important for furniture factories and large-scale engineering projects. High-quality hinges typically pass 50,000 opening and closing tests, ensuring they won’t loosen, deform, or stall over long-term use. International standards generally simulate different opening and closing angles, forces, and speeds to realistically replicate home usage scenarios.

Here are some tips for judging durability:

- Manual Opening and Closing Test: Perform dozens of rapid opening and closing cycles, observing for any jamming, unusual noises, or loosening.

- Check Spring Return Force: High-quality springs have stable return force, without sudden changes in speed.

- Observe Damping Structure Stability: For hydraulic hinges, check if the closing speed is consistent.

In a real-world engineering case, a kitchen brand experienced thousands of cabinet doors sagging within a year due to the purchase of cheap hinges, ultimately requiring a complete hardware replacement—the root cause being the hinges failing durability tests. This demonstrates that durability is one of the most crucial indicators of hinge quality.

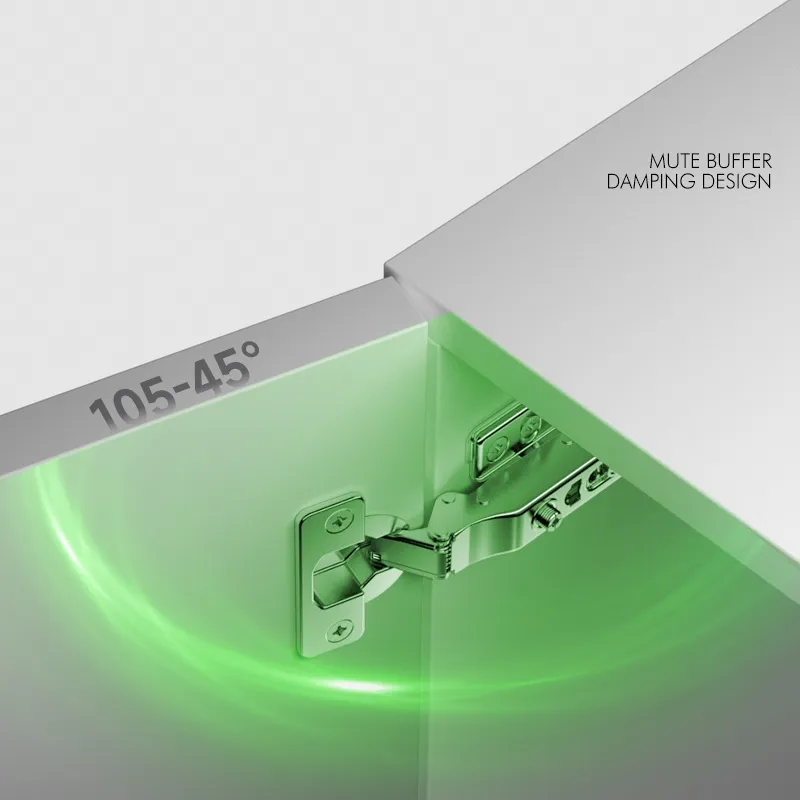

Damping Experience Affects User Experience

For modern, quiet homes, hinge damping performance is a crucial aspect of assessing hinge quality. A high-quality hydraulic system smoothly intervenes in the final 10-15 degrees of door closure, resulting in a smooth and noiseless closing action. Poor-quality damping systems may exhibit problems such as “not closing properly,” “closing too slowly,” or “closing too quickly.”

To judge damping quality, consider the following:

- Observe the smoothness of the final closing phase: There should be no shaking or jumping.

- Stability test: After opening and closing more than ten times, the damping effect should not change significantly.

- Environmental adaptability: High-quality damping oil is suitable for temperatures ranging from -20°C to 45°C and can still operate stably even with large temperature differences.

The core of damping technology lies in the oil core structure design and sealing performance; therefore, the manufacturer’s R&D capabilities significantly impact hinge quality. Currently, widely used hydraulic systems employ a dual-oil-circuit structure, maintaining a linear closing speed under varying forces. For example, high-end cabinet brands often require a closing time of 2–4 seconds to ensure optimal quiet operation.

Installation Performance and Compatibility Determine the Final Effect

Even if a hinge performs excellently in terms of materials and structure, poor installation compatibility will affect the overall hinge quality. For example, excessively high requirements for cup hole depth, poor precision of adjusting screws, or incompatible bases will affect the efficiency of installation and subsequent performance.

From the perspective of furniture factories or installers, the actual performance of a hinge can be judged in the following ways:

- Check the adjustment range: High-quality hinges typically have three-dimensional adjustment functions: front-back, left-right, and height, with a range of ±2mm to ±5mm.

- Test the installation error tolerance: Slightly misaligned holes should be compensated for through adjustment to prevent door panel misalignment.

- Assess the tightness of the fixing screws: If the screws are not tightly engaged or stripped, it indicates poor precision.

For example, a cabinet brand chose to use hinges with quick-release bases to reduce installation time, ultimately improving installation efficiency by 20%. This illustrates that hinge design not only affects furniture quality but also the efficiency of the entire supply chain. Therefore, installation performance is also a crucial factor that cannot be ignored when evaluating hinge quality.

Conclusion

Whether it’s home renovation, bulk purchasing in furniture factories, or unified selection for engineering projects, assessing hinge quality is a key step in ensuring product stability and durability. From structural design, material plating, durability testing, and damping experience to installation performance, every dimension directly impacts the user experience and brand image of the furniture. Through the six methods introduced in this article, you can more scientifically and systematically evaluate hinge quality during the selection and inspection process, avoiding after-sales problems or customer complaints caused by low-quality hardware. Excellent hinge quality not only enhances the value of furniture but also saves companies long-term maintenance costs, making it a core detail that all furniture manufacturers need to pay attention to.

About Huiso Hardware

Huiso Hardware is a manufacturer specializing in hardware hinges and drawer slides, with many years of R&D and production experience. The company offers a variety of products, including hydraulic hinges, quick-install hinges, three-section drawer slides, and concealed drawer slides, and supports OEM/ODM customization services. Huiso provides reliable hardware solutions to furniture manufacturers, cabinet factories, e-commerce brands, and project clients worldwide with its stable quality, rigorous testing, fast delivery, and scalable wholesale capabilities. If you are looking for a highly reliable hinge and drawer slide supplier, Huiso Hardware is a trustworthy partner.